Understanding the Key Role of Critical Raw Materials

A Geographical Analysis between Necessity and Industrial Sustainability

In today's global economy, the engine of the economy is profoundly affected by the use and availability of critical resources, known as Critical Raw Materials (CRM).

In an era when sustainability and security of supply chains are central to global concerns, gaining an in-depth understanding and strategic management of critical raw materials becomes imperative. Access to such resources has also become crucial to ensure the competitiveness of nations and businesses.

The European Commission proposed the Critical Raw Materials Act (CRMA) and the Net-Zero Industry Act (NZIA) on 16 March 2023 as legal frameworks participating in the broader Green Deal strategic plan. The aim is to reduce the EU's dependence on critical raw materials and promote sustainable, secure and competitive conditions in the supply chain.

Definition of Critical Raw Materials

To provide a definition of Critical Raw Materials, it’s essential to distinguish the category from Strategic Raw Materials (SRM). Both are primary resources with economic importance for the development of key sectors and for achieving the goals of the green and digital transition. The term 'critical', however, has been introduced for raw materials that are subject to high supply risks and currently lack substitutes.

The methodology to determine CRMs is based on parameters of Economic Importance (EI) and Supply Risk (RA). These materials are often characterised by their low availability, the high degree of concentration of production in certain geographical regions and the increasing demand due to technological development in five strategic sectors of the European economy: renewable energy, electric sustainable mobility, energy-intensive industry, digital, defence and aerospace.

Trends in Europe

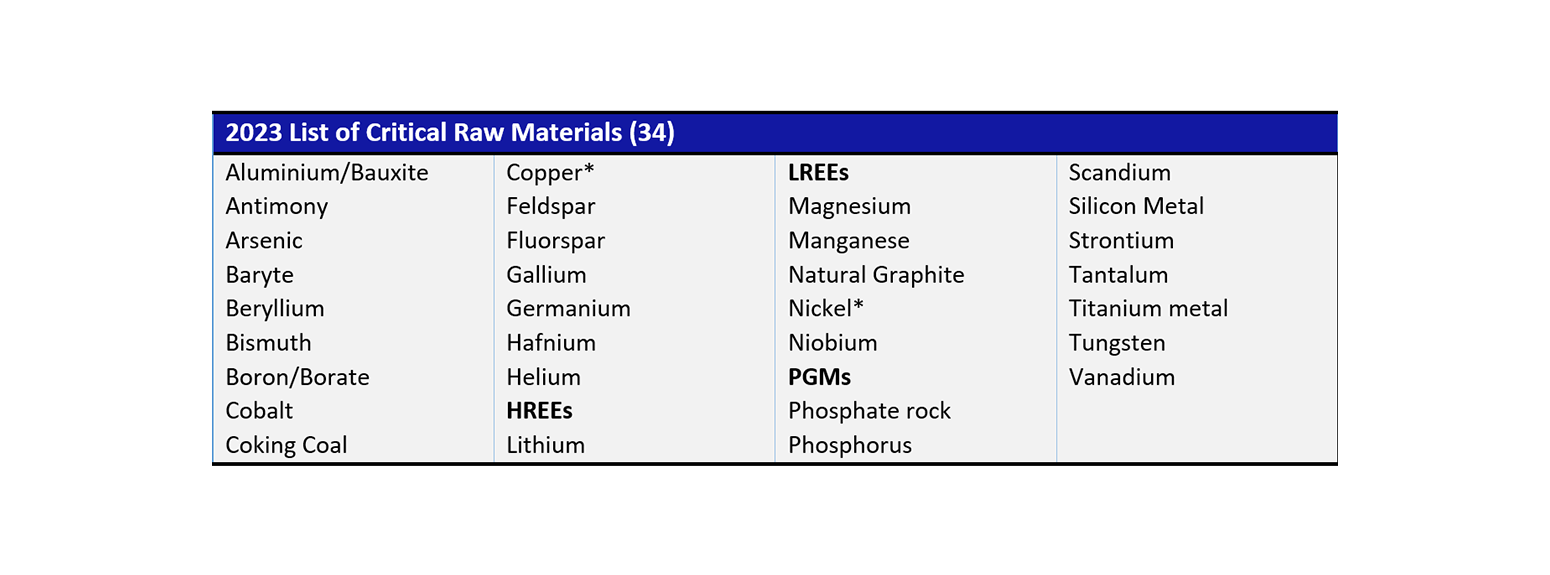

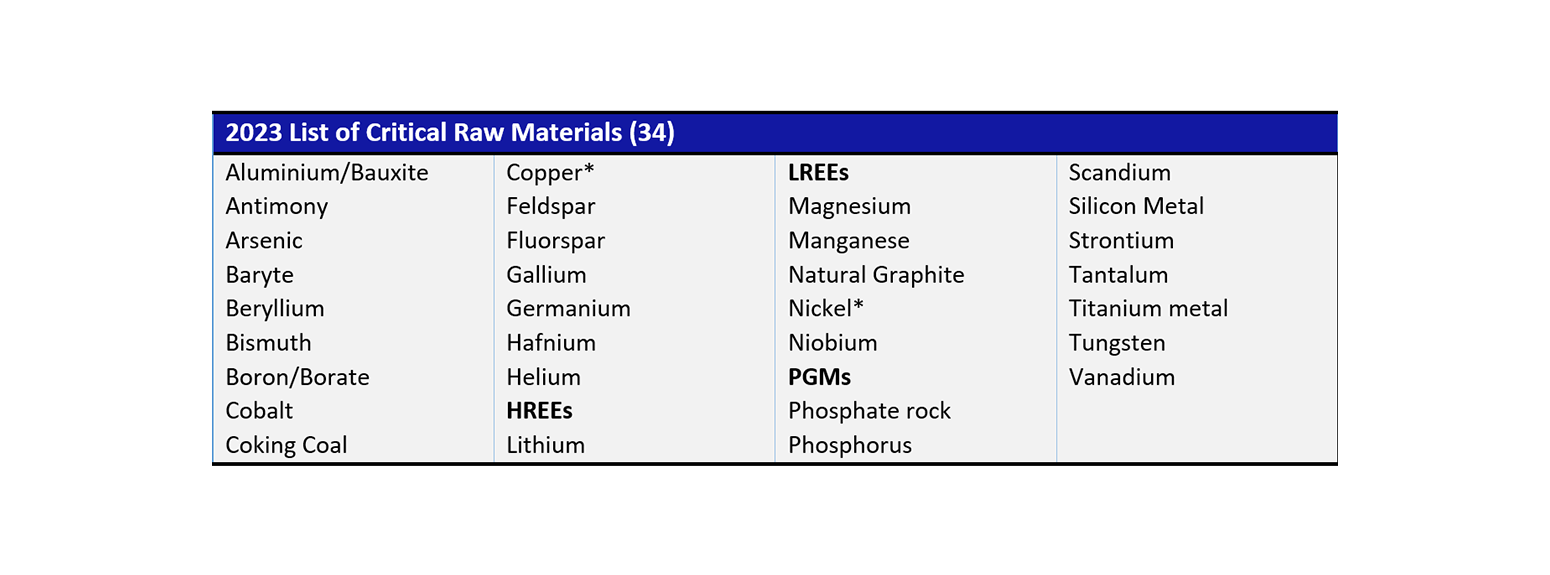

Several countries have developed detailed lists of Critical Raw Materials in order to be able to implement targeted policies. The European Union's list, updated to 2023, identifies 34 CRMs, whose main dependence comes from China, Japan, South Korea, Russia and Africa.

Table 1: List of EU Critical Raw Materials (2023)

*Copper and Nickel do not meet the CRMs criteria but are included in the list since they are considered Strategic Raw Materials (SRMs). An SRM is a raw material important for technologies that support the twin green and digital transition and defence and aerospace objectives.

The list includes 16 materials and 3 material groups of which the latter consist of 10 heavy rare earth elements (HREEs), 5 light rare earth elements (LREEs) and 6 platinum group metals (PGMs).

Of relevance, for example, is lithium, which is used for batteries. A key element in the e-mobility market, demand for lithium is expected to increase twelvefold by 2030 and twenty-onefold by 2050. Its popularity has grown significantly in recent years due to its superior performance compared to other battery technologies, such as nickel-cadmium or lead-acid batteries.

Currently, lithium is extracted from hard rock mines and underground brine deposits in Australia, Chile, Argentina, China and Brazil. The processing of lithium mineral concentrates and brines takes place mainly in China, global leader with over 90% of total production. This geographical concentration poses a significant supply risk, especially considering the dependence on countries with unstable trade policies and the increased demand for materials for the transition to a green economy. Consequently, the aforementioned critical issues can generate cascading negative repercussions.

Challenges

For example, dependence on a limited number of suppliers can create supply vulnerabilities, exposing industries to disruptions and price increases.

Furthermore, CRM extraction can have serious environmental consequences and human costs such as habitat destruction, water contamination, air and soil pollution, displacement of indigenous and local communities to make way for mining projects and health problems due to exposure to harmful chemicals. Environmental and social issues related to the extraction of the aforementioned resources, which can negatively influence the reputation of the companies involved.

To address the criticality and mitigate the risks, it is necessary to diversify sources of supply through 're-shoring' (development of national CRM supply chains), promote research and development of alternative materials and implement recycling and reuse practices following the paradigm of the circular economy.

By addressing these risk factors proactively, Europe will be able to ensure the stability of its supply chains and pursue the strategic objectives of the ecological and digital transition to a sustainable future.

The report offers a detailed analysis of each Critical Raw Material and insights into future opportunities.