Startup Tales | Hiro Robotics, the cleantech for electronic waste treatment

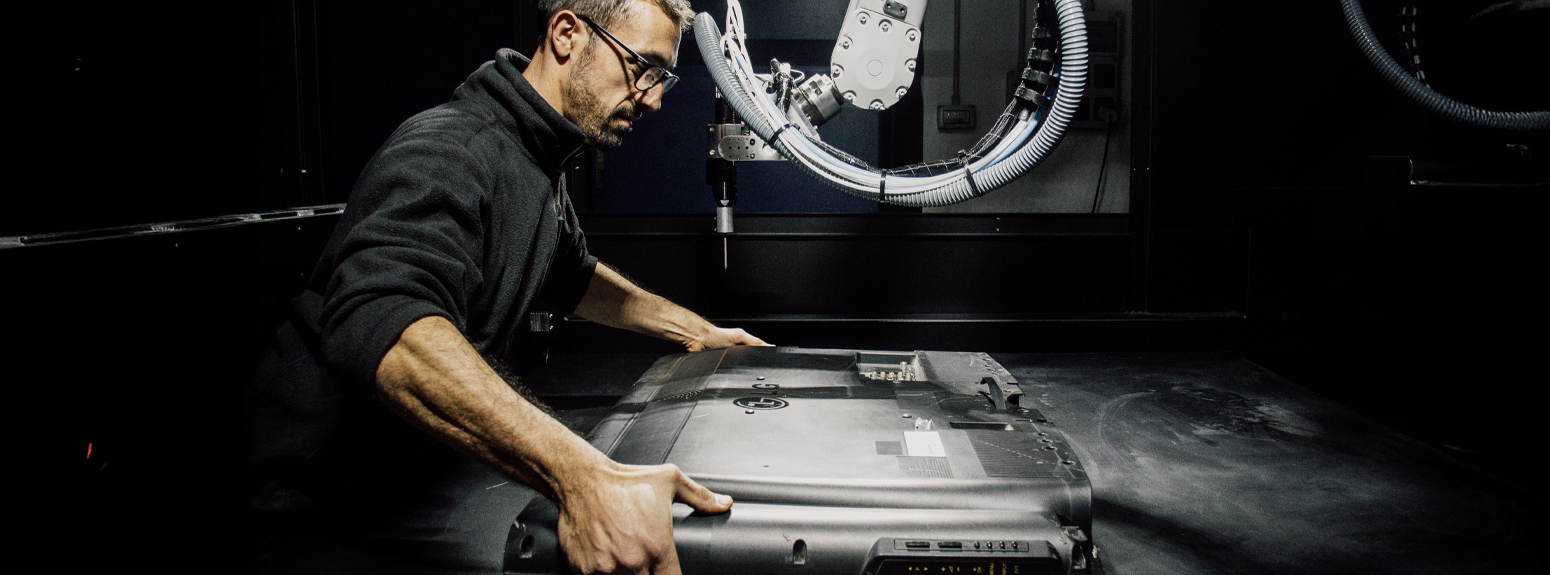

The Genoese scaleup, co-founded in 2018 by four young engineers with experience in research laboratories abroad, has developed innovative and circular technologies for the treatment of waste from electrical and electronic equipment (WEEE) thanks to the combination of robotics, computer vision, and artificial intelligence.

In an era where sustainability is a concrete necessity, a young and promising Italian scaleup stands out in the global cleantech landscape. This is Hiro Robotics, a company fully integrated into the Circular Economy paradigm, which, through the adaptation of advanced technologies typical of the industry, aims to address one of the most urgent environmental and economic challenges: the treatment and recovery of waste from electrical and electronic equipment (WEEE).

Thanks to an approach that combines robotics, artificial intelligence, and computer vision, Hiro Robotics has developed solutions capable of transforming the recycling of various types of WEEE into a value-added process, based on human-machine synergy. The fields of application range from flat-screen monitors and TVs (FPD) to industrial electronics, from printed circuit boards (PCB) to photovoltaic panels. Areas where global recycling often does not comply with regulations, with negative repercussions on the environment.

With collaborations with leading players such as the Iren Group and A2A, and thanks to a recent investment round led by Levante Group, Hiro Robotics is now looking at international expansion, working simultaneously on developing technology for disassembling electric vehicle batteries.

This latter technology allowed the scaleup to achieve third place in the In Action Esg CLIMATE 2024 call 4 ideas, initiative promoted come on Life companies of the Intesa Sanpaolo Assicurazioni Group (Intesa Sanpaolo Assicurazioni and Fideuram Vita) in collaboration with Intesa Sanpaolo Innovation Center, with the aim of providing support concrete economic development to companies bringing innovative solutions, capable of promoting a significant impact towards the transition ecological and towards a greener and more sustainable world, creating value for our country.

Birth and objectives of Hiro Robotics

The background of the cofounders

Founded in Genoa in 2018, Hiro Robotics was born from the experience of a group of millennial engineers with expertise in robotics, computer vision, and artificial intelligence: Davide Labolani (CEO), Jacopo Lottero (R&D), Tomaso Manca (Marketing and Communication Manager), and Michele Oliveri (CTO). “We worked as research engineers between France and Germany, and after choosing to create our own company, we returned to Italy to found Hiro Robotics,” recalls Manca.

The initial idea

“The idea was to develop a more precise vision system, not only through static images but also dynamic videos, allowing industrial robots to observe objects up to interaction, just like a person would,” explains the Marketing and Communication Manager of Hiro Robotics.

The objectives of Hiro Robotics

“Our intention,” clarifies Manca, “is to take technologies usually applied to the manufacturing world and, therefore, to create things, adapting them to demanufacturing, that is, disassembling to recover. An area that involves numerous challenges to face, because while an industry that makes computers has standardized processes for the various production lines, when it comes to disassembling, they present differences, even when the model is the same.”

The focus on electrical and electronic waste (WEEE)

In the early stages of the innovative startup, the cofounders focused on technology, but after the first use case, namely the disassembly of flat-screen TVs and monitors (FPD), they realized how it had value if applied in a particularly dynamic, unpredictable, and complex context like that of disassembling electrical and electronic waste (WEEE) to recover the reusable materials contained within them.

The technologies of Hiro Robotics

“From there, the first solution, TEIA, was born, which, even today, is our flagship product and is linked to the most successful use cases,” emphasizes the cofounder of the cleantech. A system for disassembling flat screens capable of processing up to 90 FPD devices per hour with sizes ranging from 17 to 65 inches, which includes 3 robots for removing the front frame, unscrewing internal components, and removing the rear part.

Subsequently, the Genoese scaleup team developed MAIA: a robotic module used for the treatment of industrial electronics, capable of removing more than 12 screws per minute from servers, inverters, industrial control electronics, and telecommunications systems, thanks to AI-based software that identifies and classifies them, and a robot that automatically unscrews them.

“These are electronic waste from the professional IT world, which have many screws. On one hand, the unscrewing and disassembly process is very important, on the other hand, these wastes have a lot of value inside, with reusable materials like rare earths,” explains the Marketing and Communication Manager of Hiro Robotics.

These are the two flagship technologies of the Genoese scaleup, accompanied by NISA: a PCB (Printed Circuit Board) sorting system based on value that, using artificial intelligence, recognizes the components mounted on printed circuits and classifies them based on the estimated value.

Hiro Robotics has also developed another technology, EOS, for photovoltaic panels. EOS handles the various stages of the disassembly process (removal of the aluminum frame, recognition and management of different models, automatic palletizing and depalletizing), processing 120 panels per hour.

The growth path: from collaborations to the investment round of Levante Capital

Despite participating in acceleration and incubation programs in Italy, the cleantech has always aimed to be self-sufficient, with particularly innovative technologies for WEEE treatment validated by concrete applications.

In fact, currently, Hiro Robotics' technologies are operational at the Volpiano (Turin) plant managed by the Iren Group through its subsidiary Amiat, and, since August 2024, at the LaboRAEE plant at the Second Casa Circondariale di Bollate (Milan) of A2A. In these two contexts, the advanced automation systems of the scaleup support human operators in the treatment of electronic waste.

To these collaborations with top players in the sector, on January 13, 2025, Hiro Robotics added an important milestone, namely the closing of a strategic investment round led by Levante Capital: a fund specializing in sustainable industrial technologies with growth potential in Asian markets.

“In our growth path,” emphasizes Manca, “we have obtained several awards, but above all, positive feedback before the investment from Levante Capital. One of our strengths is having reached December 31, 2024, in bootstrap, without relying on capital increases, but simply supported by research projects and our customers, such as the Iren Group and A2A.”

The environmental and social impacts of Hiro Robotics technologies

The technologies developed by Hiro Robotics also have both environmental and social impacts. In fact, according to the United Nations' Global E-Waste Monitor 2024 (GEM), 72 million tons of electrical and electronic waste are produced annually. “If this waste were loaded onto 40-ton trucks and lined up one after the other, they would form an uninterrupted line that could circle the equator,” exemplifies Manca. “Furthermore,” he continues, “three-quarters of this waste is not adequately treated, with low recycling rates and the amount increasing year by year.”

The intention of the Genoese scaleup is therefore to solve the recycling problem, “because 78% of waste treated non-compliantly, according to the United Nations, causes estimated damages of 78 billion dollars to people and the environment due to the substances that leak from them,” clarifies the cofounder of Hiro Robotics.

To this are added more general situations such as the open-air landfill of Agbogbloshie, located on the outskirts of Accra (Ghana), “where enormous quantities of WEEE are exported under the pretext that they are second-hand devices, but once there, they turn out to be non-functional. People then try to disassemble them manually or burn them, with tragic consequences for their health,” explains Manca.

The economic impacts of WEEE

Although WEEE contains recoverable materials worth an estimated annual value of about 82 billion dollars globally, even in the 22% of cases where they are treated compliantly, it does not ensure that part of this value is recovered. “For example, manual disassembly has high recovery rates, but it is too slow and expensive, while shredding results in a significantly low percentage of recovered value compared to what it could be,” highlights the cofounder of Hiro Robotics.

Transforming recovery into a winning process

“We believe that proposing semi-automation solutions, with robots and artificial intelligence alongside people, is a way to achieve great efficiency by processing high volumes, maintaining a high percentage of materials recovered from WEEE. This makes recovery an increasingly winning process, ensuring that treating them compliantly is also convenient, and not just a matter of ethics,” explains Manca.

Participation in In Action Esg CLIMATE 2024: a project for electric vehicle batteries

In this perspective, and aiming to address the critical issues in the treatment of waste generated by electric vehicles, Hiro Robotics applied to the call for ideas In Action ESG CLIMATE 2024, launched by Life companies of the Intesa Sanpaolo Assicurazioni Group (Intesa Sanpaolo Assicurazioni and Fideuram Vita) in collaboration with Intesa Sanpaolo Innovation Center, with the aim of providing support concrete economic development to companies bringing innovative solutions, capable of promoting a significant impact towards the transition ecological and towards a greener and more sustainable world, creating value for our country.

In Action Climate ESG in the third edition has awarded the four most innovative projects with a significant impact in support of the ecological transition, among the 140 applications received in the sectors of Sustainable and Renewable Energy, Blue Economy, Smart Manufacturing, Agritech, and Sustainable Lifestyle.

“Our goal,” clarifies the Marketing and Communication Manager of the cleantech, “is to automate more and more processes and have a system capable of treating increasingly complex waste, arriving at a solution for disassembling electric vehicle batteries, which will be one of the most relevant electronic wastes in the coming years.”

“The idea is not only to unscrew the upper shell of the vehicle battery packs but also to cut the cables, discharge them from residual current, and extract the individual cells to then recover the materials,” explains the cofounder of Hiro Robotics.

Achieving third place in In Action Esg CLIMATE 2024, the cleantech has taken another step in this direction “which allows us to get even closer to the idea we have of a system for disassembling electric vehicle batteries,” emphasizes Manca.

The prospects of Hiro Robotics

Looking to the future, Hiro Robotics intends to develop an increasingly generalized disassembly process to treat different electrical and electronic waste, simultaneously maximizing performance. “From a technological point of view, we are currently prioritizing TEIA and MAIA, as they are the ‘most ready’ solutions, already operational and on which, consequently, we are focusing the most,” highlights the Marketing and Communication Manager of the scaleup.

At the business level, however, with the investment from Levante Capital, the Genoese cleantech is starting to create commercial sales and support networks in Europe. “We are making ourselves known abroad, and after being at Pollutec Paris 2024 last November, this year we will go to Lyon and Frankfurt. Furthermore, we have agents working for us in Germany and Spain, with European expansion being our main focus,” explains the cofounder of Hiro Robotics.

Anticipating what will be the next step, namely “establishing ourselves also beyond the continent, aware of how our solution is necessary and there are markets interested in adopting it,” concludes Tomaso Manca.

All the Startup Tales