[1] Ellen MacArthur Foundation

[2] M. Tellini et al., La sostenibilità evolve: economia e finanza circolari per un nuovo sviluppo, Bancaria n.4/2022, 19/05/2022 -

[3] European ParliamentaryResearch Service. (2020). "The Role of Collaborative Robots in Sustainable Production”.

[4] ROB-E – Swarm Robotics for Education in Circular Economy. (2022). Melanie Schranz, Paul Amann, Raphaela Egger, Sabrina Schifrer.

Synergies between Circular Economy and Robotics: Towards a Sustainable and Automated Future

The integration between circular economy and robotic technologies offers economic benefits for businesses combined with greater environmental effectiveness, with the education of new generations on ecological technologies and practices crucial to addressing contemporary global challenges.

The circular economy is the reference industrial model for the development of a regenerative economy, able to untie the growth of companies and territories from the exploitation of exhaustible natural resources . When applied, the principles of circularity allow companies to adopt an innovative approach that, differing from traditional environmental issues, can play a crucial role in the industrial policy of the territories, stimulating a process of transformation oriented towards greater competitiveness, new investments and reduction of business risks.

In this scenario, the combination of circular economy and robotics can offer significant benefits in terms of economic efficiency (such as reducing costs and increasing revenues) and environmental effectiveness (such as reducing greenhouse gas emissions). Through the adoption of technologies capable of recovering precious materials such as rare metals from products designed to be easily disassembled, for example, it is possible to solve the problem of the scarcity of non-renewable resources, at the same time reducing the amount of hazardous waste going to landfills.

Industrial robots and cobots: what they are and what role they have in the realization of the circular economy

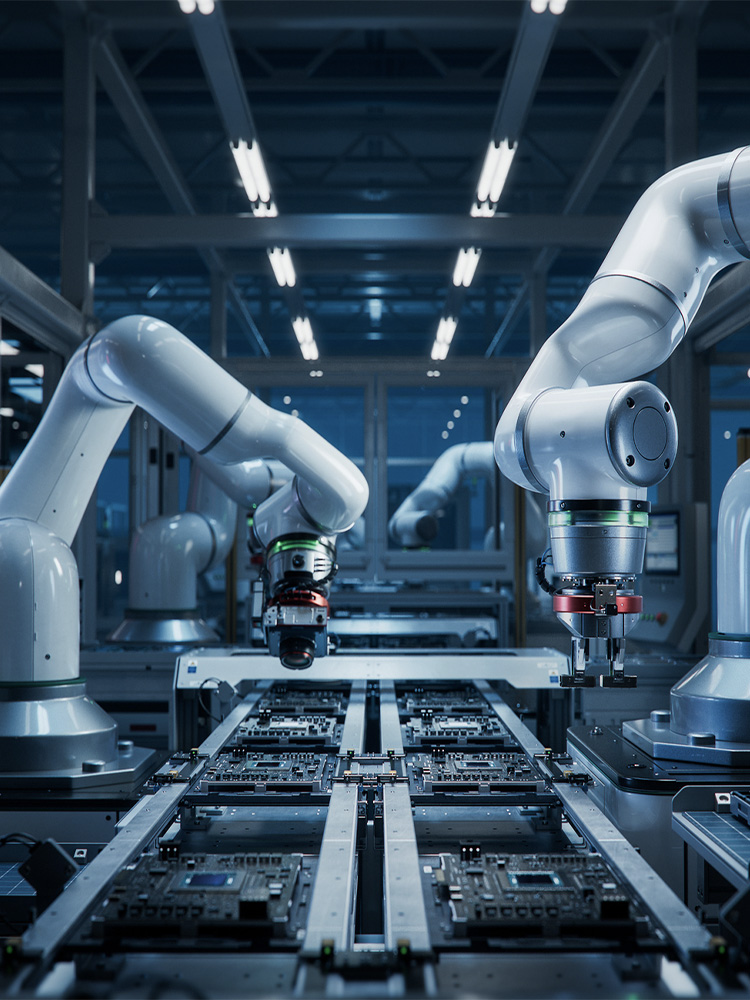

The International Federation of Robotics (IFR) has identified 13 of the 17 UN Sustainable Development Goals (SDGs) where robots can be used to save resources and help create green technologies. Industrial robots and cobots (collaborative robots) are increasingly entering the production lines of large factories - such as the Gigafactory for the production of batteries - first to respond to the SDG 12 (Consumption and Production Managers).

Cobots are emerging as key components for the realization of the circular economy by virtue of their ability to improve the efficiency and sustainability of production processes. These robots, designed to work in close collaboration with humans, are equipped with advanced technologies that allow them to interact safely and accurately with human operators. In the circular economy, cobots play a crucial role in reducing waste and optimizing resource use. Their accuracy and reliability significantly improve production processes, reducing errors and material losses.

Another key aspect is the maintenance and repair of products. Cobots can be used to perform preventive maintenance and repair tasks, identifying and correcting defects before they become major problems. This helps to prolong the useful life of products, while reducing the need for new resources, thus contributing to overall sustainability.

In addition, cobots can improve waste management within factories: by automating the transport and separation of waste materials, they contribute to more efficient and sustainable waste management, ensuring that recyclable materials are treated properly. Finally, cobots promote on-demand production and product customization, reducing the need to maintain large inventories and minimizing the risk of overproduction and waste . Thanks to their ability to distinguish different types of plastics, metals and other materials, robots ensure that waste streams are treated as efficiently as possible.

Examples of initiatives using robotics for the transition to the circular economy

Below are some business initiatives already put into practice:

- Apple has developed robots that can recover cobalt, essential for the production of batteries: "Daisy" is a disassembly robot designed to disassemble iPhone at the end of life, reducing the amount of electronic waste and recovering precious materials efficiently and accurately. The demand for this precious mineral is constantly growing, but the circular economy can reduce mining activities, investing in the recovery and reuse of cobalt and other precious minerals already present in the high-tech market.

- The Re-generation program - first of its kind in Europe developed entirely in Italy by the company Fanuc - aims to bring sustainability and efficiency in the world of automation, giving machines a second life. The objective is to respond to the growing demand for services related to product sustainability and to position itself as a reference point in the circular economy. In this perspective, regeneration involves the reintegration of industrial robots into the production chain, replacing damaged and deteriorated parts to obtain highly performing automated machinery.

- Additive manufacturing or 3D printing is another area in which robotics and circular economy intersect. This technology, in fact, allows the production of components using recycled materials, and can be used to create spare parts on demand, thus reducing the need to maintain large inventories of parts and minimizing waste at the same time.

The importance of educating new generations on emerging technologies and ecological practices: the example of the ROB-E project

In the context of current global challenges, including combating climate change and the need for greater sustainability, it is crucial to educate new generations on emerging technologies and ecological practices. In this scenario is inserted the project ROB-E, born in Austria at the University of Applied Sciences of Carinthia: an innovative educational initiative, which integrates crucial topics such as robotics, artificial intelligence and the circular economy in primary and secondary school education, and its practical and interdisciplinary approach.

Through a series of workshops, in fact, students explore the circular economy, design and build robots using recycled materials, and program them to function as a swarm of "cleaning robots". This method not only makes learning more engaging, but also promotes environmental awareness and the development of technical skills leading to a series of workshops that build on each other: after delving into topics related to the circular economy (including low environmental impact production, reuse and recycling), students design their own robots based on the circular design and bionics approach.

The robots are then 3D printed using recycled PLA, with students subsequently assembling individual (electronic) parts and programming them as a swarm of “cleaning robots” to collect and sort the waste. In this way, they begin an exciting journey with cutting-edge topics applied to everyday life situations.

The project also includes company visits and radio broadcasts, facilitating the creation of a bridge between education and the world of work. ROB-E is therefore a concrete example of how education can evolve to meet the challenges of our time, combining advanced technologies and sustainable practices to train a new generation of professionals aware and committed to protecting our planet.

Circular economy and robotic technologies: the advantages for companies and for the future of the planet

Raising awareness of the importance of these innovations is crucial as robotics in the circular economy is not only a technological advance, but also a commitment to a more sustainable and circular future. The adoption of these technologies, in fact, can help to create a more responsible economic system in which starting from the redesign of the materialproducts constantly recycle and reused, minimizing waste and environmental impacts.

The integration between the circular economy and robotics is not only an innovative solution to address the environmental and production challenges of our time, but is also a revolution destined to redefine industrial and environmental paradigms. Imagine a future in which factories operate without waste, where robots not only assemble, but regenerate products, extending their service life and reducing the demand for new resources. This synergy allows us to transform every productive sector, from fashion to agriculture, to the food industry, creating shorter, more efficient and sustainable supply chains.

Despite the initial technical and financial challenges, investment in technology is a key strategic choice for companies that want to maintain their competitiveness in an increasingly circular-oriented market. The training of a skilled workforce and the implementation of advanced technological infrastructure will therefore be crucial to take full advantage of these opportunities.

In a nutshell, the intersection of circular economy and robotics is not only a promising frontier for sustainability and industrial innovation, but a necessity to ensure a prosperous and sustainable future for future generations. Embracing this technological revolution means actively participating in the construction of a world where progress and regeneration of natural capital go hand in hand, ensuring a positive legacy for the planet.